With operating pressures up to 3,500 bar (51000 psi), LDPE plants are outstanding in the group of large chemical plants. Ethylene is compressed by a combination of different piston compressors. In the so-called primary compressor, fresh ethylene is fed into the process and compressed to approx. 275 (4000 psi) in a multi-stage process. In most cases, cylinders are located on the same crankshaft, which add a partial flow of the educt. This is drawn off behind the reactor and fed back to the primary compressor. Especially in older plants a separate machine (the booster) is used for this purpose. The further increase to the extreme reactor pressure is done in 2 stages by means of the so-called secondary compressor or hyper compressor.

Within the scope of the design of these compressor systems, a comprehensive numerical check (“Study of Pulsation”) of the interaction of the compressors with the connected pipelines and vessels is carried out. This is necessary to avoid acoustic resonances. These can lead to excessive pressure fluctuations in the system, which are called pulsations. For new plants these studies are normally carried out by the compressor manufacturer. Various parameters affect the accuracy of these studies. For this reason, a metrological check of the actual pulsation level after or during commissioning is useful.

There are different orientation values for permissible pressure pulsations. From a mechanical point of view, pressure pulsations cause forces on pipes and supports. On the one hand these dynamic forces must be absorbed by the supports and on the other hand it must be avoided that mechanical natural frequencies of the components can be excited. Various parameters affect the accuracy of these studies. For this reason, a metrological check of the actual pulsation level after or during commissioning is useful.

The best way to achieve vibration control in a reciprocating compressor system is to minimize the pressure pulsations. To do this in a traceable way it is necessary to measure the pressure pulsations during operation. In the area of the booster and the primary compressor pressure sensors can often be used in a simple way. Due to the extreme pressures and the already high load of the components in the area of the secondary compressor this is not possible here.

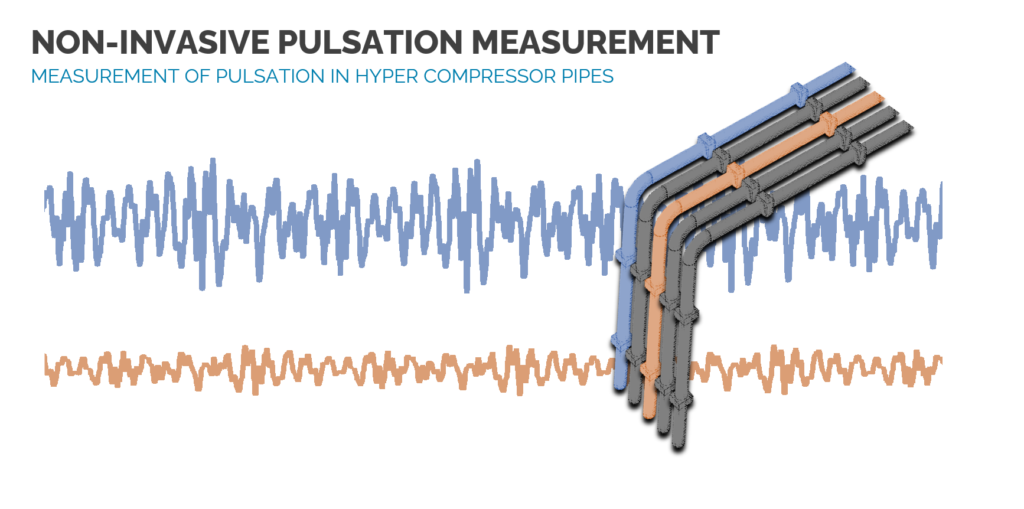

Indirect measuring methods are used here to measure the dynamic deformation of the pipe walls due to the changing internal pressure. Even for the extreme wall thicknesses in the highest pressure range, these methods can be used to precisely record pressure pulsations at practically any point of the compressor system up to the reactor. In combination with a multi-channel measurement, not only standing waves can be clearly identified. A direct determination of the speed of sound is also possible in this way.These are extremely valuable data for the adjustment of a numerical model of the piping acoustics.

We would be pleased to support you in a metrological evaluation of the pressure pulsations and a subsequent optimization in your plant.