Pressure Pulsation can significantly affect der lifetime of a compressor valve.

The consequences are ranging from mechanical failure of spring, stem or poppetdue to excessive impact velocities of seat/guide and poppet up to complete failures of the valve body.

A valve malfunction can affect the pressure pulsation situation in a plant and may result in excessive pressure pulsation and high pipe vibrations.

You can verify valve malfunction by

1.The impacts of the poppet may be detected by acceleration sensors. The information is related to the valve position. (Check your Condition Monitoring System).

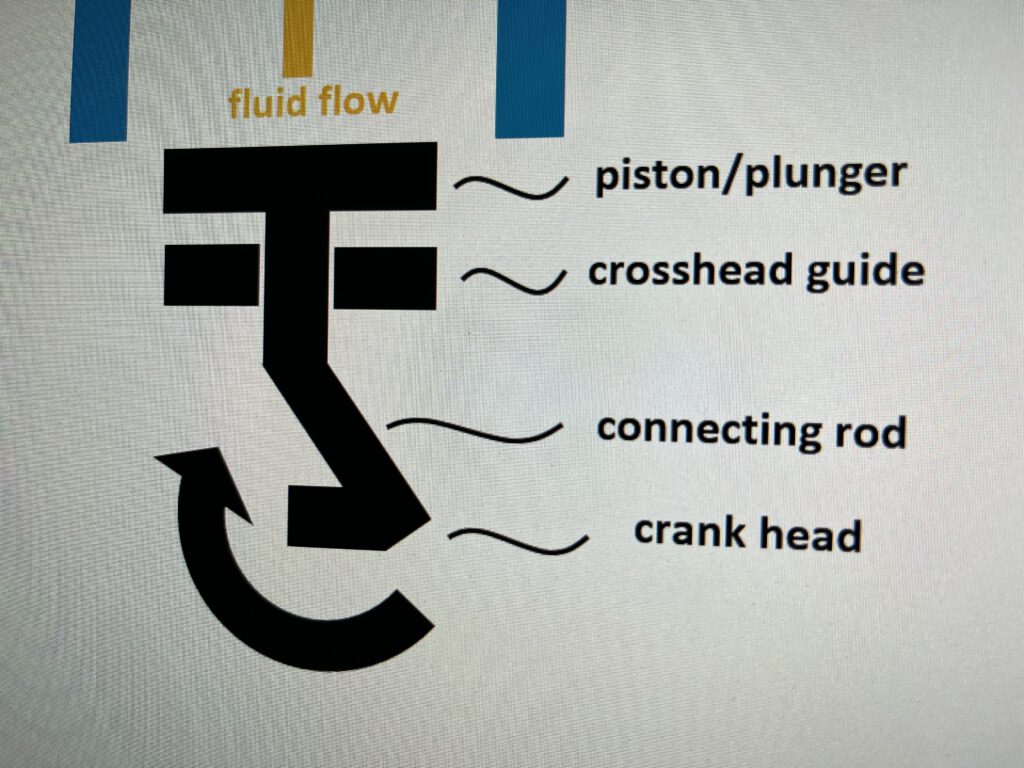

2.The change in the cylinder gas forces can be monitored by means of strain measurements, for e. g. at the connecting rods.

3.The fluctuations in suction and discharge pressures can be identified by pulsation measurements.

The presentation at the Uhde Plant Improvement Conference 2024 is backed up with an experiment. We are providing a video here in case you want to watch these experiments again or show them to one of your colleagues.