Construction work is making progress

Current interim status of our new office building at the future location in Hörstel-Dreierwalde. Our future premises will soon offer enough space to provide additional employees with a pleasant and …

We provide effective solutions for customers around the world in the optimization, troubleshooting and evaluation of industrial plants based on metrological and numerical investigations.

Our Services.Examples.

Focused on acoustics of pipes and structural dynamics, our services support customers in various phases of their plants life-cycle.

In case of repeating failures, excessive vibrations and weak reliability, a systematic investiagtion to reveal the chain of cause and effect is carried out using various methods. We are performing troubleshooting investigations for our clients all over the world. We are a relieable partner and we operate on short-notice.

No technical system is perfect. By optimising the structural mechanics and the piping acoustics of an industrial plant, significant reductions in structural vibrations can be achieved and thus an improvement in plant availability.

Within the framework of continuous improvement, the requirements for process and operational safety are increasing. An important contribution in this context is the performance of ongoing external audits. In addition …

The planning and realisation of a large-scale chemical plant (like LDPE or EVA) is a major project with running times of several years. Within the scope of the planning and …

In case of unclear boundary conditions for vibration phenomena in technical systems, for the purpose of data writing during restart of proplematic machines or to evalute the vibration level of complex systems, temporary vibration monitoring is an effective tool.

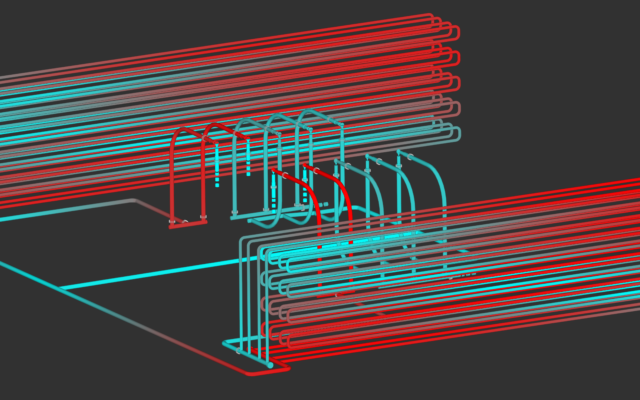

With time, we have developed and improved our toolbox for an effectice vibration mitigation and optimization.

One highlight is the Dynamic Pipe Support. This is our patent-pending tuned mass absorber, that can be tuned on-site and while the equipment is in operation.

This enables us to provide long-term solutions to excessive vibrations that are caused by mechanical resonances within days.

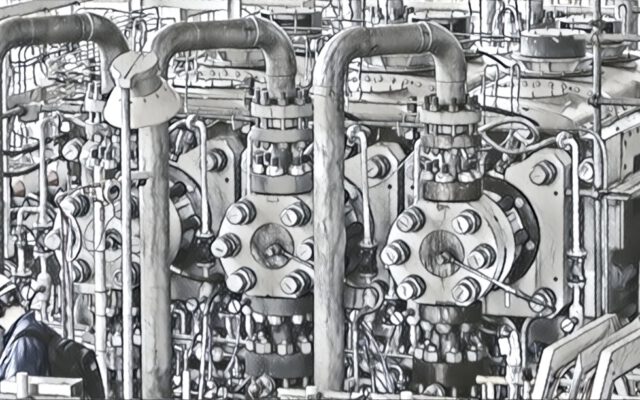

We are experts in handling of pressure pulsations and structural vibrations in industrial applications. We are providing high level consultancy services to clients around the world. With more than 25 years of professional experience, powerful measurement and analysis tools and state of the art simulation software we can guide you to take the right actions in the optimization of the dynamics of your plant.

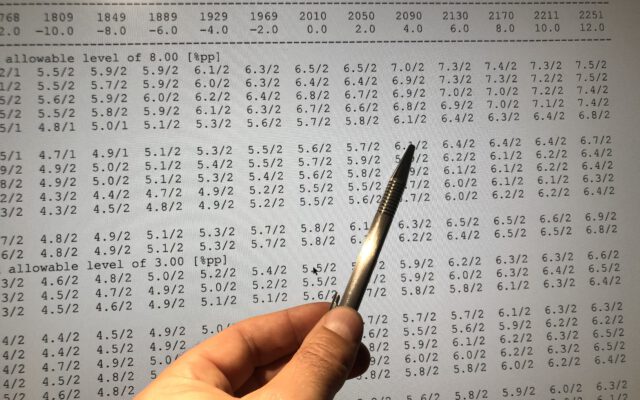

A comprehensive and reliable database is the foundation of our business. For this reason, we combine metrological and theoretical investigations so that we can make meaningful technical decisions together.

A state of the art chemical plant has normally been carefully tuned to avoid mechanic and acoustic malfunctions in terms of resonances.

We are supporting our clients in troubleshooting and optimizations projects by means of realistic numerical studies.

Increased vibrations are often the result of a complex chain of effects of excitations and amplifications. An efficient analysis and mitigation requires not only profound expertise but also a certain amount of experience. From hundreds of projects in over 10 years of professional experience we can offer you both.

Experience from hundreds of real life investigations at reciprocating and turbo machinery. We are recognized experts for vibrations and pulsations in LDPE/EVA plants.

With our measurement technology for vibrations and pulsations we achieve an incomparable depth of detail. This will impower us to focus on the things that really matter and to take the right actions.

For our numerical vibration and pulsation studies we apply knowledge, experience and state-of-the-art software. Whenever possible, we align our simulations with the results of metrological investigations. In return, we can provide customized solutions.

For us, carrying out a project means taking responsibility. Reliability, openness and honesty are our key values. We are a reliable partner for you in every phase of our cooperation.

Current interim status of our new office building at the future location in Hörstel-Dreierwalde. Our future premises will soon offer enough space to provide additional employees with a pleasant and …

In many cases pipe vibration are a consequence of a mechanical amplification due to a natural frequency of a pipe segment between its supports. Discharge pipe bends of hyper compressors …

Target audience and format The target audience for this webinar are operators of LDPE/EVA plants. This full-day seminar is designed for a duration of 6 hours. A vivid discussion with …

With the help of a metrological examination of the plant during normal operation it can be ensured that the dynamic load of the plant is within the expectation range and …

We are proud to sponsor the LDPE-PIC! Join us on 17 – 19 June 2024, Riga, Latvia. You can register now at https://reg.eventmobi.com/LDPEPIC_Participant/register and apply for a special discount using …

You have found a reliable partner who can offer you technical services at the highest level. We are looking forward to the future cooperation with you.

You can contact Dr. Jansen via phone under +49 171 323 4860 and Dr. Tetenborg via +49 160 93 20 60 81 .